Carpoly's Three-Dimensional Automated Colorful Production Line Successfully Trial-Produced

2025-08-07

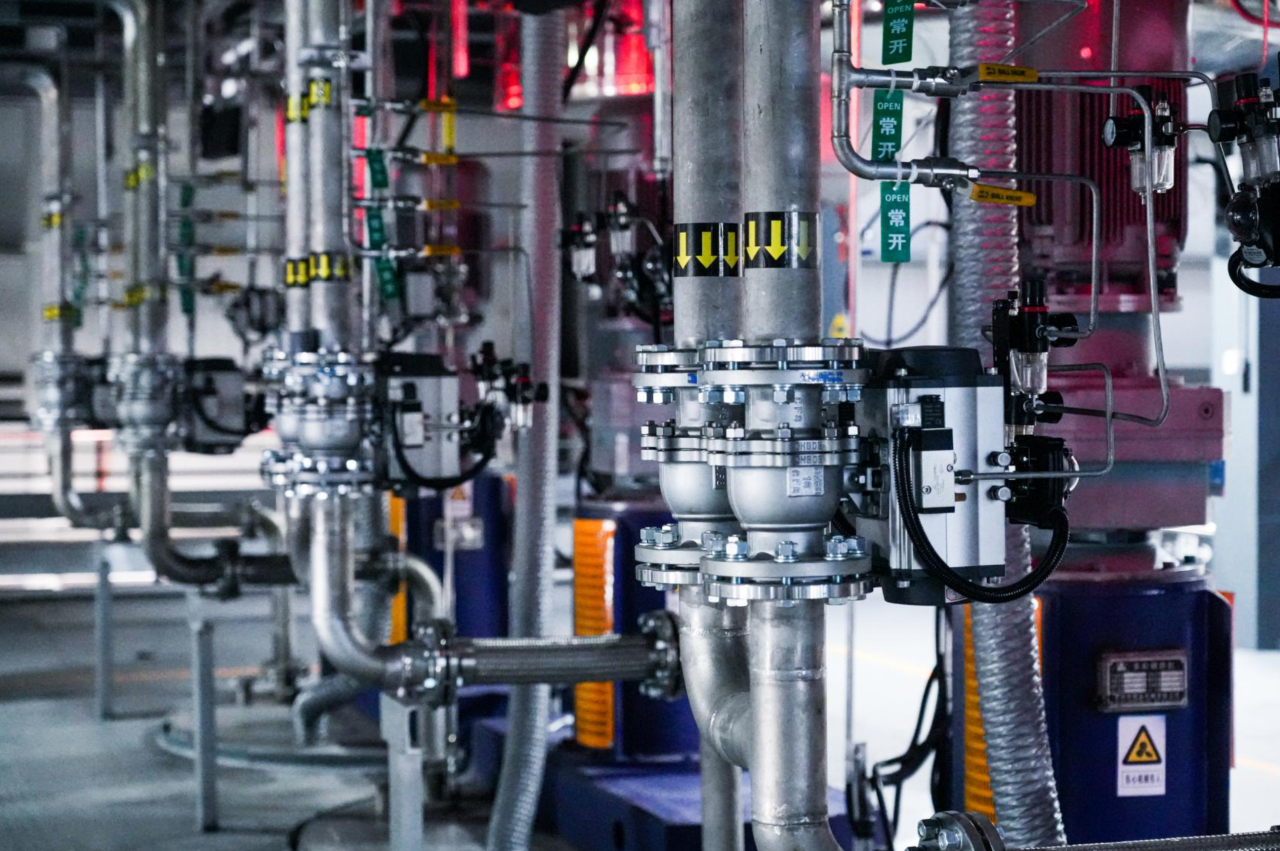

July 2025 · Jiangmen, Guangdong — Carpoly's independently developed first 10,000+ ton three-dimensional intelligent colorful production line has completed verification and trial production. This production line deeply integrates three-dimensional layered technology with industrial internet technology, aiming to meet the annual market growth demand of 50% in recent years. It marks that Carpoly has stepped into a new stage in intelligent manufacturing and national capacity layout in the field of stone-like paint.

Part.1

Efficient Linkage of National Intelligent Production Line Network

Accurately Matching Retail Demand

With the Duruan base as the hub, the new production line links factories in Anhui, Sichuan and Foshan, building a "3-hour quick response circle" covering East China, Southwest China and South China. Equipped with automatic material conveying, customized beating cylinders, color mixing/mixing cylinder production equipment, the production line breaks through the limitations of planar layout with process orientation to build a three-dimensional production mode.

Part.2

Five Major Technological Innovations

Establishing Production Standards

1. Innovation in three-dimensional layered technology: Through vertical space optimization, it can significantly improve the efficiency of material circulation, and simultaneously promote the dual standardization of processes and procedures;

2. Intelligent batching system: The weighing accuracy of liquid materials and the stability of powder conveying are greatly optimized. With the automatic additive module, it can realize one-click switching production of multiple formulas;

3. Green production system: Integrating automatic atomization sterilization process and intelligent dust collection system, VOCs emissions are reduced by 50% and energy consumption by 20%, fully meeting the "dual carbon" requirements;

4. Full-process data traceability: The holographic monitoring of key process parameters is linked with the quality defense system, the abnormal response speed is significantly improved, and the product qualification rate can be maintained at a high level sustainably;

5. End automation integration: The palletizing and packaging accuracy of robots have achieved intelligent upgrading, efficiently replacing manual heavy physical labor, and the continuity and stability of production have been greatly enhanced.

The project innovations will effectively reduce operating costs and lay a solid foundation for creating a product portfolio of "high quality + high cost performance".

Part.3

Service Ecosystem Upgrade

Providing Integrated Solutions

Relying on the advantages of production line intelligence, Carpoly has launched the "Retail Customer Empowerment Plan": through the data interconnection between the DCS system and the construction end, it provides a full-chain service of "formula recommendation - rapid sampling - construction guidance". For example, the system can automatically adjust weather resistance parameters according to the climate in South China, and combine with logistics information sharing to realize seamless connection between "production and construction", promoting the transformation of the service model from a single "product delivery" to an "integrated solution".

Part.4

Leading Industry Upgrade

Accelerating High-End Transformation

The successful implementation of this production line not only consolidates Carpoly's leading position in the field of stone-like paint, but also drives the industry to upgrade from "labor-intensive" to "intelligent manufacturing". Carpoly's core technologies such as layered production layout and intelligent batching are expected to become new industry standards, driving technological collaboration in the upstream and downstream industrial chains, and helping China's coating industry to accelerate its transformation to high-end and low-carbon.

With the full release of the national intelligent production line network, Carpoly expects its market share in the stone-like paint retail market to further increase in 2025. Looking forward to the future, in line with the 14th Five-Year Plan, the company will take product and technological innovation as the core engine. Through the capacity expansion plan of continuously adding multiple colorful production lines in 2026, while expanding the production capacity scale, it will accelerate the upgrading of production automation and product system diversification, injecting new "intelligent manufacturing" momentum into the high-quality development of the coating industry.